“Choosing Not to Discard” Gives New Life to Uniforms― Rigaku’s Upcycling Story ―

Uniforms turned into wall clocks and coasters!?

- ■Wall Clock

-

A simple, functional clock made from old uniforms.

Its material? “PANECO®,” a recycled fiber board.

- ■Coaster

-

Coasters with marble-like patterns that catch the eye.

Each piece is unique in color and design—truly a “one-of-a-kind recycled item.”

- ■Mobile Bench

-

Benches with casters made from “Nunock” blocks, born from uniforms, are installed at the Tokyo and Yamanashi factories.

Their transformation is so striking that you can’t help but say “Wow!” just by looking.

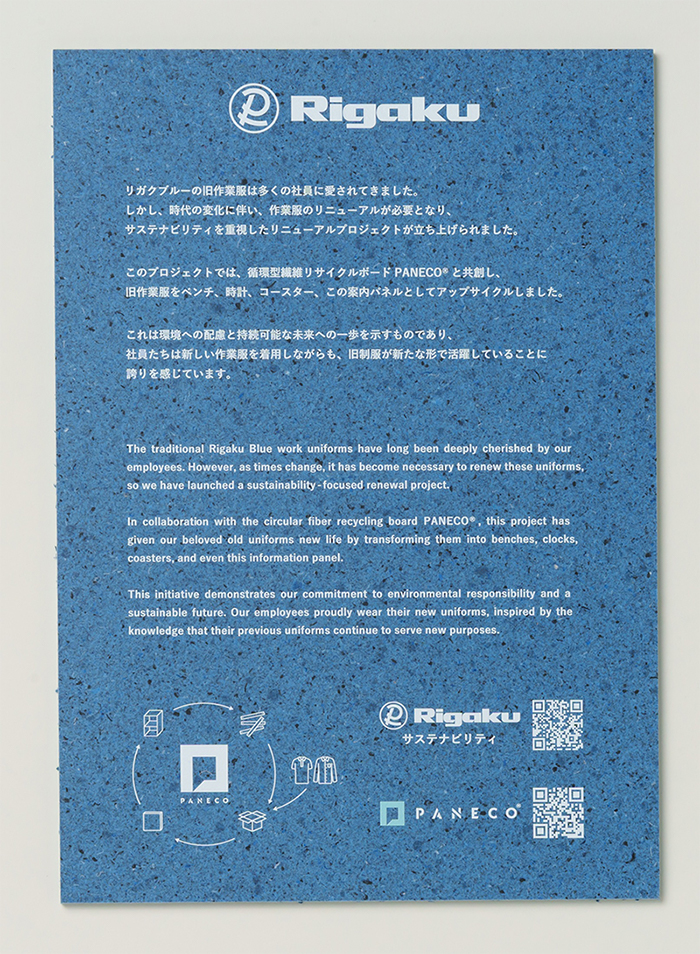

- ■Information Panel

-

Includes English explanations to communicate with international visitors.

The spirit of the project is captured in this single panel.

Driven by a sense of “mottainai” and a spirit of challenge

In October 2023, Rigaku introduced a free dress code policy outside of safety-critical areas, allowing employees to choose their work attire. This initiative aimed to create an environment where everyone could express their style.

Furthermore, work uniforms for production areas were redesigned in September 2024 to be more functional, comfortable, and stylish.

Simply discarding the large volume of old uniforms would mean waste. But these items supported our work for years—we wanted to breathe new life into them.

Thus, our upcycling project has begun.

- Beautifully Reborn

- In collaboration with Work Studio Co., Ltd. and Moririn Co., Ltd., we upcycled relatively well-preserved and unused uniforms into PANECO® boards and Nunock blocks using material recycling techniques.

PANECO® is a sustainable material that produces zero textile waste and can be recycled.

To add new value to long-loved uniforms, we established the motto for this project: “Beautiful regeneration,” “Resource circulation without waste,” and “Environmentally conscious resource collection.”

- From Uniform to New Form: 5 Steps to Rebirth

-

1.Collection

Used uniforms were collected from all the operational sites in Japan, sorted into good and damaged items, and packed into boxes.

Approximately 2,000 uniforms—contained in 52 boxes—were collected at the end.

One 2-ton truckload of collected uniforms 2.Disassembly

With support from welfare facilities, zippers and buttons were carefully removed from uniforms. Every step was done by hand, with care and time.

3.Shredding

Once stripped down to fabric, the uniforms were finely shredded for reuse as raw material.

4.Molding

The shredded fibers were compressed and molded into PANECO® boards and Nunock blocks.

Molding boards from processed uniforms

Molding blocks from processed uniforms 5.Utilization

The newly reborn items are now used across company locations.

Coasters were distributed to all employees.

Also Used as Energy

For uniforms that are too damaged or dirty for material recycling, we have outsourced upcycling to Eco Mining Co., Ltd. They converted the old uniforms into RPF (Refuse Paper & Plastic Fuel) through thermal recycling.

RPF is used as an alternative to coal for factory heat sources and power generation and is estimated to reduce CO₂ emissions by about 33%. This effective use of waste also helps reduce landfill volume.

It reflects our spirit of making full use of things.

- A Cycle that Cares for Society

- This project isn’t just kind to the environment—it’s also kind to people.

Disassembly work was done in collaboration with welfare facilities located near the collection sites.

Removing zippers and buttons one by one was a delicate task that had to be done manually. Individuals with disabilities at welfare facilities were involved in this process.

In addition to outsourcing part of the PANECO® production process to welfare facilities, a portion of the upcycled product sales is donated monthly to these facilities.

This supports stable employment opportunities across four axes: “location,” “time,” “work”, and “wages”.

Through manufacturing, we support people’s motivation and pride in work—this is part of our mission.

- A Step Toward Global Connection

- According to the United Nations Environment Programme (UNEP), each year, 92 million tons of clothing are discarded worldwide, yet only about 8% is recycled.

Though changing this reality might be difficult, we are taking on the challenge in our way.

- Rigaku’s Unique Creativity Born from Inspiration

- Uniforms are more than just fabric—they hold the “time of workers” and the “history of the company”.

Working on this project, we also had an opportunity to reflect on ourselves.

Instead of throwing old uniforms away as waste, we asked: “What could this become next?”

This kind of out-of-the-box thinking is a true reflection of Rigaku’s spirit of craftsmanship and innovation.