Rigaku Corporation, a global solution partner in X-ray analytical technology and a group company of Rigaku Holdings Corporation (Headquarters: Akishima, Tokyo; CEO: Jun Kawakami; hereinafter “Rigaku”) has received the 2025 Local Commendations for Invention (sponsored by the Japan Institute of Invention and Innovation), for three patented technologies. This marks Rigaku’s third consecutive year of receiving the Special Award.

Encouraged by this recognition, Rigaku will pursue further possibilities in X-ray technology as it strives to create solutions that bring innovation to the field.

Special Award

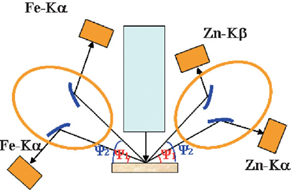

Fluorescent X-ray Analysis Contributes to Quality Control in Alloyed Galvanized Steel Sheets

This invention is a fluorescent X-ray analytical technology that can analyze deposition quantity and composition with greater accuracy than conventional methods. To reduce the impact of differences in depth of measurement1, two optical systems with differing angles of incidence and extraction are used, enabling all coating layers to undergo depth analysis. This technique allows for precise composition data across all coating layers, contributing significantly to quality control in alloyed galvanized steel sheets used in products such as automobile bodies.

1 Depth of Measurement: The depth within a sample from which information can be obtained

Award Name: Kinki Local Commendation for Invention (Osaka Invention Society Chair’s Award)

Invention Name: Fluorescent X-ray analytical equipment and Method (Patent No. 4262734)

Inventors: Yoshiyuki Kataoka, Eiichi Furusawa, Hisayuki Kohno

Product details:https://rigaku.com/ja/products/xrf-spectrometers/wdxrf/simultix-15

Honorable Mention for Invention

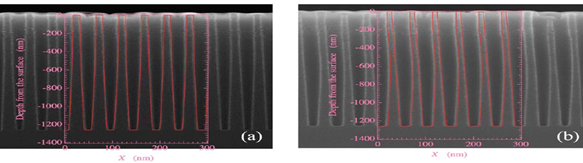

Analysis of Nanostructure of Semiconductor Deep Holes Contributes to R&D and Quality Control in High-Aspect-Ratio 3D-NAND Memory

As semiconductor devices adopt increasingly three-dimensional configurations, wafer surfaces now feature fine patterns reaching depths of around 10 µm. Because the shape of these fine patterns directly affects device performance, high-precision cross-sectional profile measurement is required. Generally, simple geometric models are used to analyze SAXS data, but they are insufficient for detailed shape analysis. This invention is capable of evaluating the shape of any shape with high robustness, and can perform detailed analysis of slight changes in shape, tilts, and bends. This technology is applied globally in R&D and in-line quality control for state-of-the-art semiconductors such as high-aspect-ratio 3D-NAND2 memory, contributing to product optimization, improved yield, and stable product performance.

2 3D-NAND: Next-generation flash memory that uses 3D structure to achieve high capacity and performance

Award Name: Kanto Local Commendation for Invention (Honorable Mention for Invention)

Invention Name: Method, equipment and program for microstructure analysis (Patent no. 7100897)

Inventors: Yoshiyasu Ito, Kazuhiko Omote

Product details:https://rigaku.com/ja/products/semiconductor-metrology/cdsaxs/xtraia-cd-3200t

Honorable Mention for Invention

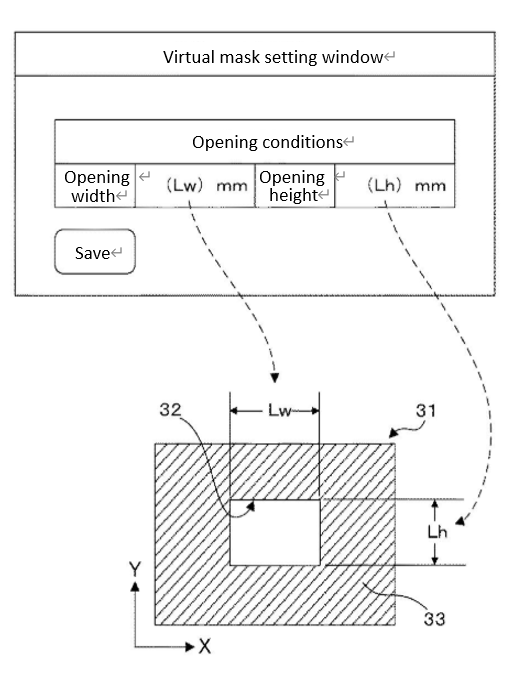

X-ray Diffraction Virtual Receiving Slit for Reduced Labor and Greater Flexibility

In X-ray diffraction (XRD), a receiving slit (“slit”) is used to adjust resolution and intensity during measurement. In conventional systems, the slit’s width and height had to be physically adjusted or replaced to achieve the desired resolution, resulting in limited flexibility and time-consuming replacement.

This invention employs a semiconductor detector with positional resolution, enabling the data acquisition area to be selected electronically. This innovation achieves higher resolution and intensity than the conventional physical slits while reducing labor requirements. As a result, it enables rapid response to a wide range of measurement conditions, significantly improving efficiency in R&D and quality control.

Award Name: Kanto Local Commendation for Invention (Honorable Mention for Invention)

Invention Name: X-ray analytical device and X-ray diffraction measurement method (Patent no. 5944369)

Inventors: Shintaro Kobayashi, Tohru Mitsunaga, Koichi Kajiyoshi, Kazuyoshi Arai

Product details:https://rigaku.com/ja/products/components/detectors/hypix-3000

About the Rigaku Group

Since its establishment in 1951, the engineering professionals of the Rigaku group have been dedicated to benefiting society with leading-edge technologies, notably including its core fields of X-ray and thermal analysis. With a market presence in 136 countries and regions and some 2,000 employees from 9 global operations, Rigaku is a solution partner in industry and research analysis institutes. Our overseas sales ratio has reached approximately 70% while sustaining an exceptionally high market share in Japan. Together with our customers, we continue to develop and grow. As applications expand from semiconductors, electronic materials, batteries, environment, resources, energy, life science to other high-tech fields, Rigaku realizes innovations “To Improve Our World by Powering New Perspectives.” For details, please visit rigaku-holdings.com/english

Press Contact:

Sawa Himeno

Director, Communications Dept., Rigaku Holdings Corporation

prad@rigaku.co.jp