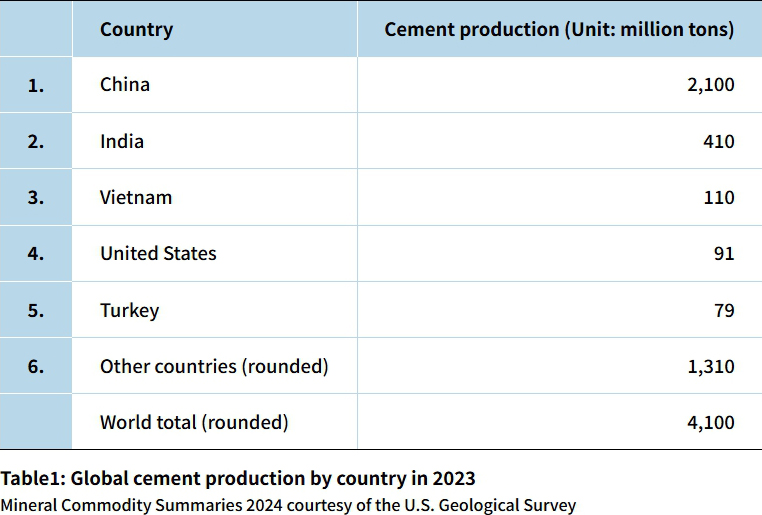

The cement industry is one of the largest sources of CO2 emissions, following the energy and steel industries. It is estimated that cement production accounts for 5-8% of worldwide CO2 emissions from human activities. Globally, 4.1 billion tons of cement are produced annually (Table 1: FY2023 results), with approximately 800 kg of CO2 emitted per ton of cement. Half of these emissions come from the decomposition of calcium carbonate, while the other half results from fuel used in transportation and firing.

In Japan, the cement industry emits 25.5 million tons of CO2 annually. Given the urgency of climate goals, efforts are focused on reducing greenhouse gas emissions by 46% by FY2030 (compared to FY2013 levels) and achieving full carbon neutrality by 2050.

In recent years, research institutes and private companies have focused their efforts on developing various technologies aimed at reducing CO2 emissions. These innovations are advancing towards practical applications of carbon recycling technologies that capture and fix CO2 emissions as inorganic carbonates, which can then be recycled into raw materials for cement (as an alternative to limestone) or used in civil engineering materials. The next challenge lies in maximizing the amount of fixed CO2 while reducing the cost of producing recycled CO2-absorbing concrete, which is currently two to three times more expensive than regular concrete.

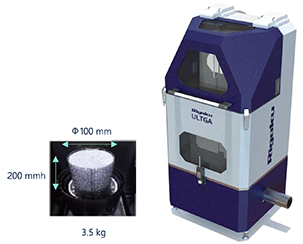

Rigaku has recently developed the “ULTGA” CO2 fixation measurement device, based on concepts and specifications provided by Professor Ippei Maruyama from the Graduate School of Engineering at the University of Tokyo. Taiheiyo Consultant Co., Ltd. successfully completed the verification process for the equipment.

The traditional method for measuring the amount of fixed CO2 involves drying several kilograms of concrete in a vacuum dryer, then grinding the material into uniform powder over several days using equipment such as a universal testing machine, hammer, and coarse crusher. The powder is then measured multiple times using small samples of just a few tens of milligrams. Typically, this process takes about a week.

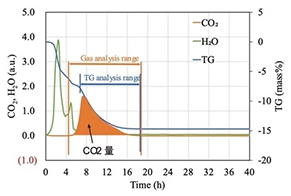

However, the ULTGA device significantly simplifies this procedure. It can directly heat φ10 x 20 cm concrete specimens used for strength tests, without the need for pretreatment such as crushing. The device allows for easy measurement of the generated CO2 concentration in approximately two days (Figures 2 and 3).

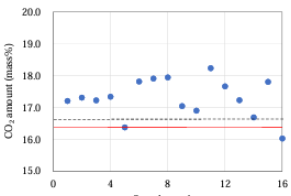

The measurement results from this device are consistent with theoretical values, which are calculated based on the composition ratio of the materials used when mixing the concrete and the amount of CO2 in each constituent material (Figure 4).

[Research Grants]

This research was conducted as part of the Green Innovation Fund Project/Research and Development on Standardization of Evaluation of CO2 Fixation in Concrete (Project Number: JPNP21023), a commissioned project of NEDO (New Energy and Industrial Technology Development Organization).

The orange area represents

the amount of CO2 in the concrete.

Measurement results for 16 groups of concrete samples after

pulverization using the conventional method (blue dots).

The black dotted line represents the theoretical values

calculated from the constituent materials,

while the red line shows the results measured using the new ULTGA device.

All sample measurements shown are the average of three trials.