Green Steel is an initiative aimed at reducing the environmental impact and ensuring the sustainable use of resources in the steel industry. It refers to steel products that minimize carbon dioxide (CO₂) emissions during the steelmaking process and contribute to the realization of a circular economy.

It’s said that the steel industry is responsible for approximately 7-8% of global CO₂ emissions, and the transition to Green Steel is crucial for achieving a decarbonized society and promoting the efficient use of resources. In blast furnace steelmaking, coke (coal) is used to reduce iron ore, generating large amounts of CO₂. On the other hand, recycling scrap steel in electric arc furnaces helps reduce the use of fossil fuels and establish a resource-circulating manufacturing process.

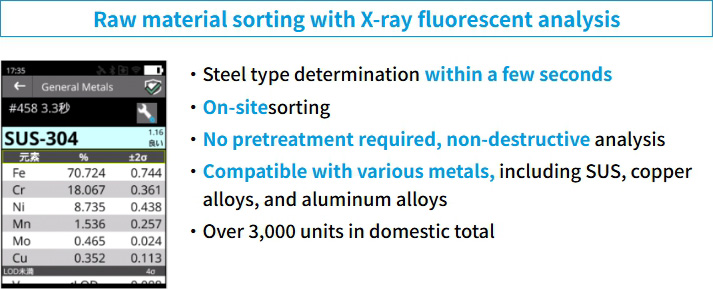

To promote the reuse of scrap iron, advanced sorting of raw materials and effective element management during the manufacturing process are essential. By utilizing X-ray fluorescent analysis, which allows for rapid elemental analysis without sample pretreatment, in the management of raw material sorting processes, the quality of steel products can be improved, and the optimal use of resources can be achieved.

Click here for details of XRF