Environmentally friendly cars (Electric Vehicles: EV, Hybrid Vehicles: HV) have spread rapidly and power semiconductors are becoming increasingly important to increase their power efficiency. Railway transport and home appliances also use high performance power semiconductors more and more to improve energy efficiency.In particular, semiconductor substrates with wide band gap materials including Sic (Silicon carbide) and GaN (Gallium Nitride) are increasingly used. These materials have merits such as excellent pressure resistance and rapid switching ability compared with conventional Silicon (Si) substrate. They are attracting attention as the substrate material of choice for next-generation power semiconductor devices.

In general, semiconductor devices tend to be impacted by metal contamination during the manufacturing process. This contamination impacts the device’s performance and reliability significantly.By measuring and managing the metal contamination quickly and accurately, we can bring out the maximum performance of power semiconductor devices, increase yields in the manufacturing process and reduce waste. Metal contamination management is a crucial factor to enhance the competitiveness of power semiconductor manufacturers, especially for the high reliability devices required for the severe operating conditions of EV, HV, or railway vehicles.To solve these problems, power semiconductor manufacturing processes often use TXRF (Total Reflection X-ray Fluorescence) for metal contamination measurement.

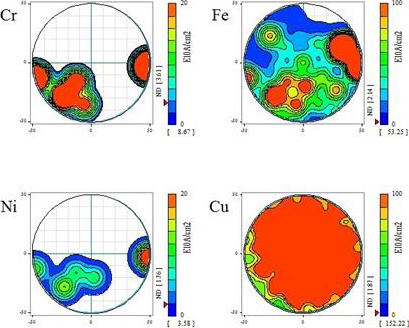

Rigaku’s TXRF solution provides functions such as “full-mapping” including wafer edge measurement, “extended diffraction line avoidance” to avoid the disturbance peak specific to compound semiconductor substrate, and “hydrophilic VPD” to achieve the high accuracy and high sensitivity metal contamination measurement for the whole surface of the Sic and GaN substrate. Rigaku contributes to improve the global environment by providing TXRF-based metal contamination measurement solution for power semiconductor manufacturer.

Click here for details of TXRF 3760

Click here for details of TXRF-V310